About Us

Since 1997, Progressive Machine Works has been providing innovation, quality, and value to our customers small part production requirements.

Industry is constantly changing

At Progressive Machine Works we strive to anticipate the road ahead. Over twenty years ago we began to implement robotic systems as a key technology which would allow us to provide our customers with better parts at competitive prices. Many others said it was impossible, but we let the results speak for us; loyal customers that keep coming back.

Industry is constantly changing

At Progressive Machine Works we strive to anticipate the road ahead. Over twenty years ago we began to implement robotic systems as a key technology which would allow us to provide our customers with better parts at competitive prices. Many others said it was impossible, but we let the results speak for us; loyal customers that keep coming back.

What brings our customers

back time after time?

What brings our customers back time after time?

Value through automation is one reason but more than that, it is our commitment. All of us at Progressive Machine Works want our customers to know that we are here to provide more than just a great finished product, we want to build a relationship founded on trust and great service.

How do we help you succeed?

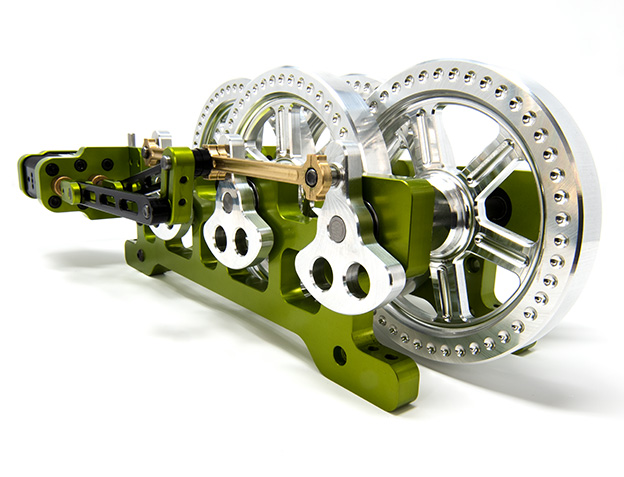

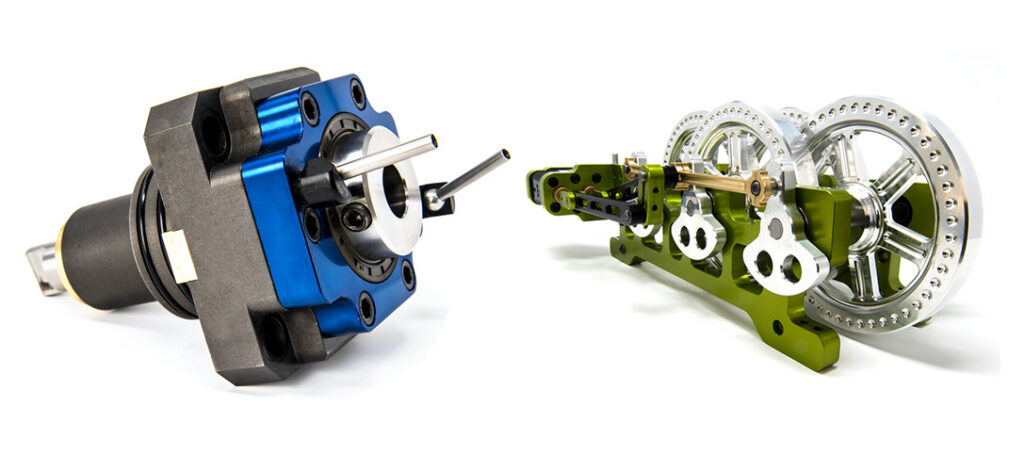

What type of parts do we make?

Progressive Machine Works manufactures production runs of small parts.

Most of the parts we make fit in the palm of your hand, weigh under 50 pounds and our machines and systems reflect that. While the size of our parts may be small, the scope of materials that we work with is not. We regularly produce components from: aluminum, high temperature plastics, plastics, phenolic, alloy steels and stainless steels as well. Check out our gallery for some samples.

PMW Advantage

What sets us apart from our competition?

A never-ending desire to exceed your expectations. Our shop is filled with state-of-the-art CNC equipment and automation systems. Six axis robots, gantry loaders, automated pneumatic loaders and bar feeders compliment most of the machines at Progressive Machine Works. This level of automation allows us to produce more quality parts in a shorter time frame than conventional machine/operator systems.