On many occasions, after sending a quote to a customer, the response is “How come so much?” or, “Why is the delivery so long?” Each time these questions are asked it falls to me to patiently explain the inner workings of a machine shop. Unfortunately, most customers are unaware of the manufacturing process from start to finish. With this in mind, it is our desire at Progressive Machine Works to take a few minutes and describe what it takes to make your part. In doing so I hope to answer a few of your questions and perhaps even save you some money as you consider the design of your next product.

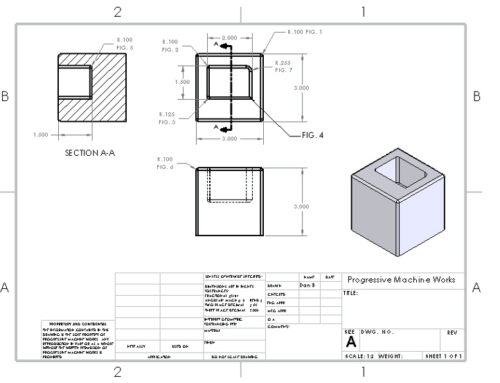

As each journey begins with the first step, in our case it is the request for quote. You, the customer, send us a drawing with all your specifications and material requirements and we begin the process of sourcing material and analyzing the part to determine the most efficient and economical means of making the component. We also need to consider any other processes that need to be carried out to take the part to completion. These might include heat treating, anodizing and in some cases, plating. These processes are outsourced to reliable vendors and their costs are added to the quote.

Two important considerations for us in quoting are the parts complexity and the material it is made from. Brass, for example, will machine significantly easier than stainless steel. Even with stainless steel the machinability of the material is dependent on the grade of stainless requested. The material type and complexity of the part, which can encompass aspects such as high tolerances or difficult to machine surfaces, can affect our ability to automate the production process as well. The more we can run the part unattended the lower the cost for you, the customer. Some parts, because of complexity, simply cannot be run using automation and they require a very skilled machinist to setup and run in order to maintain the quality that we strive for at Progressive Machine Works.

On large volume, complex, high tolerance parts we will spend the time to source the best tooling for the job and make the best fixturing we can to move a large quantity of parts through the system. With the larger volume the cost of these extra steps and the extra effort is easily amortized over the larger number of parts and may amount to a few pennies extra per piece. If the quantity of parts required is low it is not economical to make the extra effort to automate or to purchase the optimum tool for the job. At times we may have two or three people look at a drawing to determine the best means of making your part. Utilizing the varied experiences in machining among our employees we can often find innovative ways to economically produce a component.

Also, in regards to material sourcing, we have developed and continue to develop excellent relationships with our material vendors. As a volume producer of parts in Edmonton we enjoy excellent pricing on materials such as stainless steels and aluminum. Costs do fluctuate over the year and we do our best to maintain your pricing. Occasionally, if your price increases, it is often because the material cost has gone up. Added fuel surcharges from our suppliers are a particularly nasty cost killer. Added to this is material availability. Some materials, even though they are in the catalogue, are not readily available. As with anything, supply and demand dictates what we can get and how quickly we can get it. While it might seem a bit ironic, being an officially metric country, metric material sizes are very difficult to source. Usually we have to get this sourced from the U. S. and the shipping costs can be horrendous. It helps if the designer or engineer is familiar with what is actually available quickly and economically when specifying their requirements. The best question to ask yourself is, “Do I really need that or is there something easier and cheaper?” At Progressive we are willing to help with those questions. We may not have an answer all the time but it can pay big cost dividends to mine our experience.

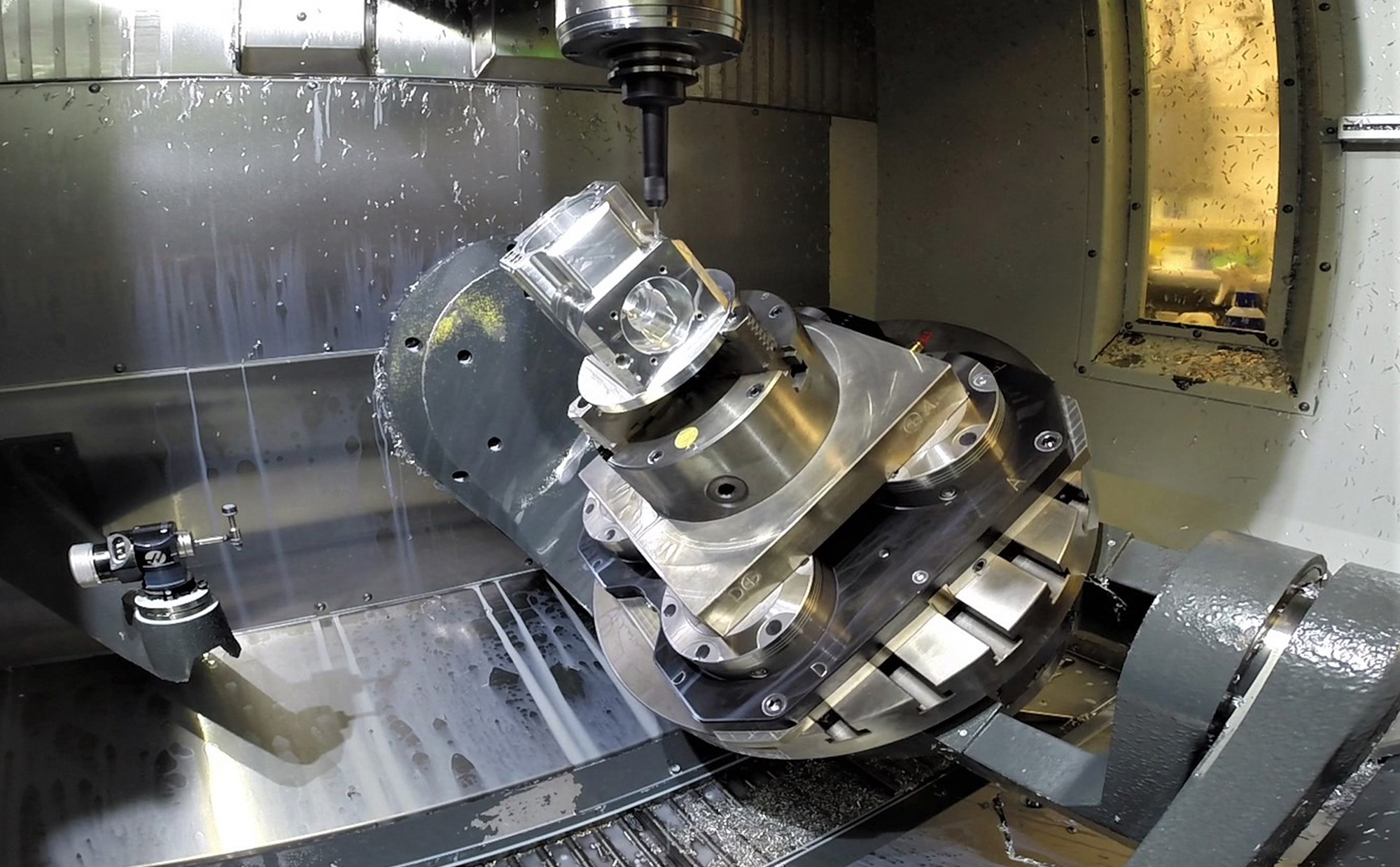

When you send as an RFQ we may have some additional questions for you. The number one question we ask is, “How many will you make in a year?” We need this information to help us determine the best method for producing your part. If you make 10000 per year we will set up one of our six axis robots to load the part. If you make five a year or it is a onetime deal we will not go to such lengths to make your part. It is simply not economical to go to the trouble of setting up a robot for five parts. One of the things we do here at Progressive is offer a “Just in Time” service if you desire to take installment deliveries of 10-50 parts per month every month. We have pallet systems in place, along with machines with a large number of tools in the magazine, that allow us to run 2-3 parts of each part number a day, every day. We may have these machines set up to run multiple part numbers but in a low daily volume. You get manageable monthly deliveries and you benefit from the price break that normally comes with a larger volume purchase. This method also allows us to take advantage of unattended operation. The machinist loads in the parts during the day and does his programming and setups. At night, when no one is here, the machine runs your parts. Unattended running means more hours for us to machine in and cheaper prices for you.

Unattended machining is what we specialize in at Progressive Machine Works. If the part is suitable to automation due to its material requirements, complexity and volume, we will always make an effort to automate. The automation of larger volume production runs greatly impacts the bottom line in regards to part costs. If you can’t accept shipments in the thousands of parts all at once we can work with you to realize the benefit of automation’s low cost by breaking up your shipments over a number of months.

Another question we might ask is, “When do you want delivery?” At Progressive Machine Works one of our chief operating mantras has always been, and will continue to be, on time delivery. We do our best to deliver when we say we will and we are proud to say we keep our word. Occasionally things do happen that prevent deliveries from being on time. Material deliveries from our suppliers, secondary processes such as anodizing or plating cannot always be controlled. Admittedly, we can also make mistakes and we always strive to ship parts that are correct. If something does go wrong, rest assured we will not leave you in the dark. That being said, please be aware that we may just say “No” to your delivery requirements. We strive to be fair to all our customers and if it is not possible to fit in your requirements for delivery we will not move aside another customer to “make it happen.”

It is also important to remember that a partial shipment will usually not make the delivery any quicker. When we quote it is based on time. If a part requires two operations we will run all the parts through that one operation before switching the machine over to the second operation. If we need to stop midway through the production run and setup on the second operation, run a few parts than go back to the first operation to finish off the run, we lose time and therefore we lose money. We have invested significant capital in fixturing, tooling and machinery to reduce and simplify the changeover processes but be aware that it is costly and time consuming to do partial runs. If it will not adversely affect our schedule we can accommodate these requests but inevitably there is a surcharge to rush through a partial shipment. If secondary processes are required, such as plating, the fees associated with that are often based on batch minimums. If the partial shipment requires an extra fee because of batch costing it will be passed on to you. While many vendors and customers practice a JIT system it is beneficial when a customer carries some inventory. This will guard against delivery back logs and those unforeseen demands from your own customers. At Progressive we have worked with many of our customers to maintain an inventory of their most common parts to help them do just that.

Once we have sent you your quote and we have come to an agreement on delivery, the manufacturing process begins. The part is placed in the schedule according to the machine it needs to run on. Part size, complexity and material type play a role in determining this selection of equipment. If required, tooling is ordered along with the material. The machinist will then begin the process of programming the machine and assembling the required tooling and fixturing to make your part. Simple turned parts may only take a few hours to do while complex parts requiring many processes could take days to program, setup and prove out. Once the machine is up and running the machinists and operators will monitor tolerances and dimensions. They will replace tooling as it becomes dull and worn and spend time removing chips from the machine as production continues. Complicated parts with high tolerances will require more monitoring while simple parts may require a check only once a day. Material type plays a big part in this too. Stainless steels or glass filled plastic will eat through tooling quickly while tools running in aluminum can literally last for thousands of parts. Tooling usage also affects the cost of your parts.

Our QC department will also monitor the parts while they are being run and also before they are shipped out the door. Once the parts are machined, if required, the part cleaning crew gets to work deburring parts, performing quality checks and packaging them up. The deburring department uses a variety of tools to accomplish their task. Files, scrapers, vibratory deburring machines, grinders and sanders are the most common. Chips and coolant from the machining process are washed off and the parts are packaged so they are not damaged when they are shipped to you or to the secondary vendor.

If the parts required a secondary coating or plating process they are again inspected when they are returned to Progressive. Quality is important to us and we have established our own in house quality control systems.

To summarize, the following items affect the cost of your parts and their delivery

- Material type and availability

- Quantity of parts

- Delivery timetable

- Products designed for manufacturability

- The ability to automate the manufacturing process.

- Tolerances and complexity.

Hopefully I have been able to enlighten you to some of the steps involved in manufacturing your parts. Remember, Progressive Machine Works is here to make things work for you.